Manufacturing

The production phase of a developed design is fully overseen by our Project Management team. After completing the design and content of the Production Manual—and in consultation with all stakeholders—we begin the search for a reputable factory to carry out the manufacturing of your product.

We leverage a robust international network of reputable OEMs and manufacturing partners across Western Europe and Asia. Drawing on our deep expertise in cross-regional production management, we are able to strategically align each product’s technical requirements with the most capable and specialized manufacturer for optimal results.

Our involvement extends beyond production. After manufacturing, we continue to provide support by creating and refining the necessary technical documentation. This includes product websites, promotional content, user and service manuals.

Once the prototype has passed rigorous testing and the As-Built documentation is complete, the development team will prepare a detailed Production Manual. This manual will outline all construction steps, list the necessary tools and custom-designed jigs, and include supplier information. It will act as the definitive reference for assembling the product, covering sourcing details for every required component.

The procedures outlined in the production manual serve as the foundational guideline for planning production at the selected manufacturer. It is the manufacturer’s responsibility to translate these specified processes—such as machining, molding, casting, and assembly—into an efficient, repeatable and scalable production workflow. This includes optimizing operations to meet volume targets while maintaining quality and consistency across all production runs.

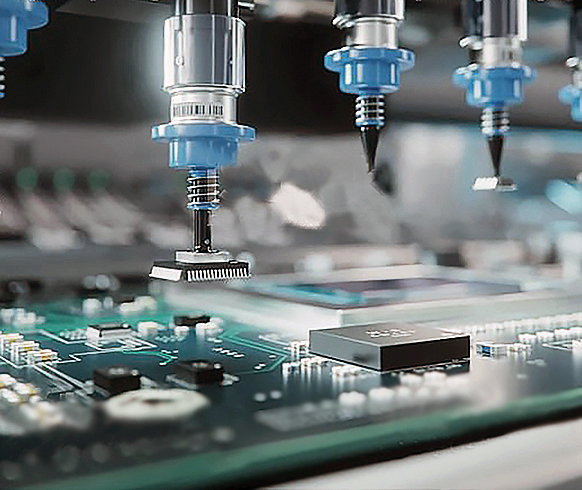

The chosen manufacturer begins production, assembling all specified components into the final product. Numerous companies contribute as suppliers, providing electronic and mechanical parts, as well as semi-finished products. Together, these elements form the supply chain that supports the assembly line and enables the construction of the complete product.

Quality Assurance Managers inspect all semi-finished products and components used in the assembly process to ensure they meet the required quality standards, as defined by both the development team and the client. Throughout manufacturing, they monitor production to maintain these standards. Our partner in Hong Kong, China, SAPL oversees the entire Asia-based OEM/manufacturing process—from factory audits to the final pre-shipment inspection.

Once the finished product comes off the assembly line, its functionality is checked at multiple stages. Following quality control and functional testing, each unit is documented with a QC report and handed over to the logistics department for packaging. From there, transportation is arranged in batches through a designated shipping provider.

The finished product is now transported—safely and fully insured—from the manufacturer’s facility to you. From there, it moves on to an outbound logistics hub for further distribution via Third- and Fourth-Party Logistics (3PL/4PL) providers. This distribution process is initiated and managed by you, the Product Owner, ensuring delivery to various customers or distributors.

Many 3PL and 4PL distributors offer additional services such as order fulfillment. A 3PL warehouse typically provides comprehensive e-commerce fulfillment solutions, including warehousing, shipping and receiving. Beyond these core functions, they often deliver value-added services such as returns processing (RMA), cross-docking and kitting. These services are essential for delivering high-quality after-sales support to your international wholesale locations and their customers.

More Specifics...

The full scope of manufacturing high-end audio and automation systems goes far beyond what we can explain on a single page. These processes involve precision assembly, rigorous quality control, specialized materials and acoustic tuning — all critical for ensuring reliability, longevity & pristine sound reproduction. If you're interested in how we approach professional-grade production or want to discuss specific manufacturing aspects, just reach out by phone or email.

Abilities driving results

A review of project outcomes and supporting data shows that 92% of our projects met the agreed development timeline—a steady improvement from previous years. This progress is the result of ongoing enhancements to our workflows, proactive risk management and improved team coordination. We remain committed to refining our approach to ensure your product is delivered reliably and on schedule.